What Is Industrial Automation?

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machineries in an industry to replace a human being. It is the second step beyond mechanization in the scope of industrialization.

The top 10 Industrial Automation Trends are

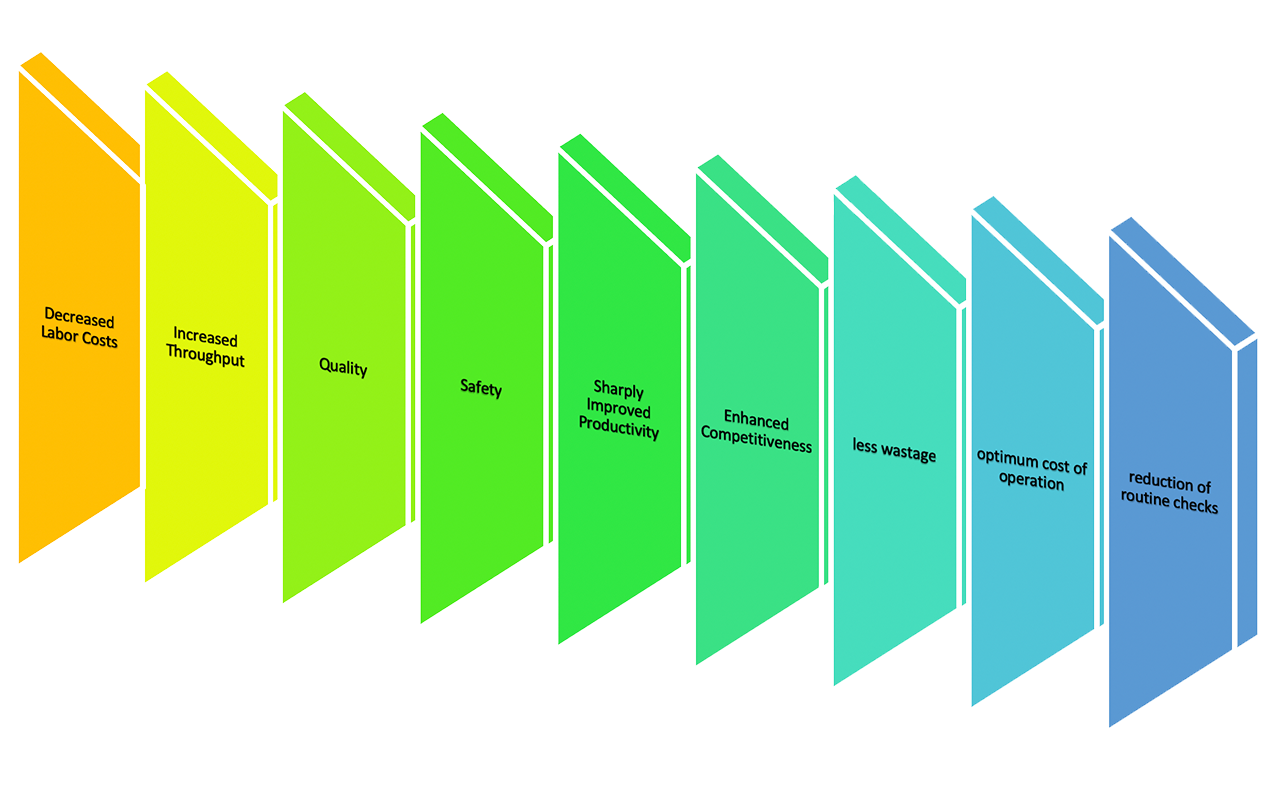

How Automation Helps Your Business?

By automating tasks, industrial automation and robotics offers tremendous advantages, as some are mentioned below

Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator. Further, industrial automation does not require other employee benefits such as bonuses, pension coverage etc. Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company. The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it.

Lower Operating Cost

Although many companies hire hundreds of production workers for a up to three shifts to run the plant for the maximum number of hours, the plant still needs to be closed for maintenance and holidays. Industrial automation fulfills the aim of the company by allowing the company to run a manufacturing plant for 24 hours in a day 7 days in a week and 365 days a year. This leads to a significant improvement in the productivity of the company.

High Productivity

Automation alleviates the error associated with a human being. Further, unlike human beings, robots do not involve any fatigue, which results in products with uniform quality manufactured at different times.

High Quality

Adding a new task in the assembly line requires training with a human operator, however, robots can be programmed to do any task. This makes the manufacturing process more flexible.

High Flexibility

Adding automated data collection, can allow you to collect key production information, improve data accuracy, and reduce your data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes.

High Information Accuracy

Industrial automation can make the production line safe for the employees by deploying robots to handle hazardous conditions.

High Safety

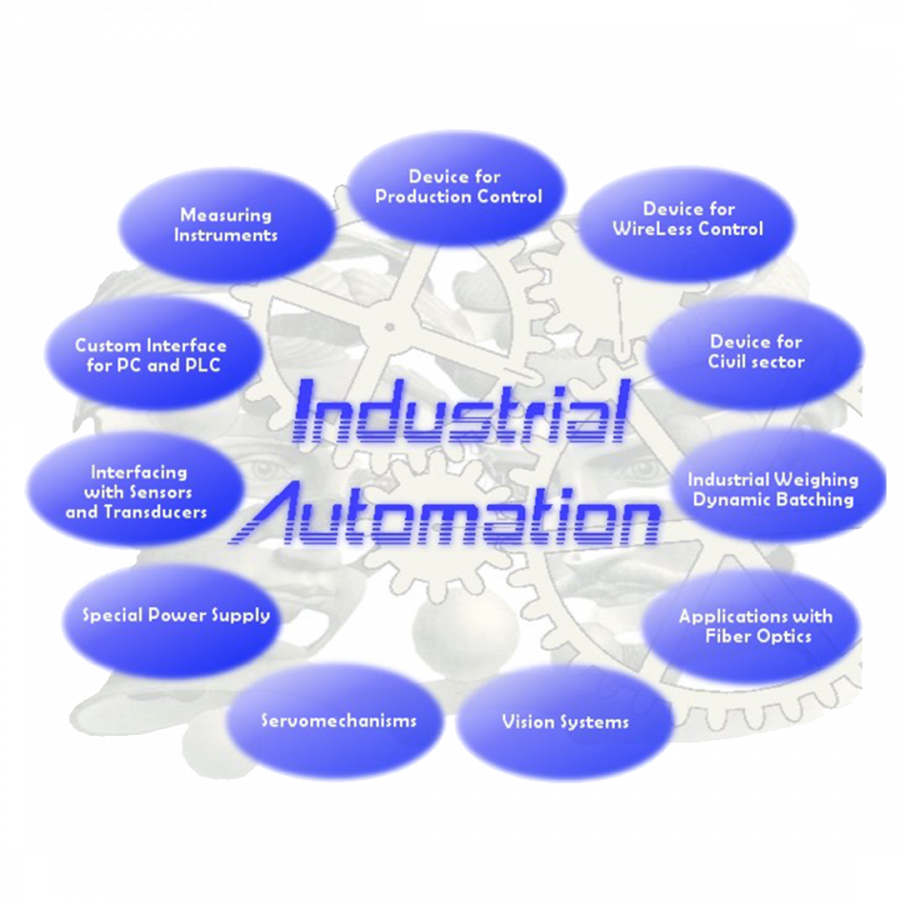

Our Services

Involta offers a broad range of services such as

Designing

Automation consultation

Manufacturing or ordering

Maintenance and after sales services

Integrating, installation and implementation

The services list is including but not limited to below mentioned devices and systems

Sensors

Controls

PLCs

Drives and Motion Control

Process P&ID

Location Plans (LP)

Instrumentation

Instrument Index (lnX)

Specification Forms (SP)

Installation Details Dorms (ID)

Design Circuit, LV, HV

Purchasing, Global Part List (PL)

Vendor List (VL)

Panel Shop

Our Design

In our designs and implementations, we use the best quality products from a number of well-known and standard suppliers. We have long-term relationships with a wide range of industrial controls suppliers and guaranty the quality and maintenance accordingly.

Our Mission

Our mission is to help and improve our customers’ businesses by creative automation solutions. We empower business and serve the society by increasing productivity, reducing costs, improving quality and enhancing safety.

About Us

Involta Automation Inc. is a Quebec registered company to provide the most modern industrial automation solutions serving the Canadian industries for a better productivity and efficacy.

Involta is owned by Mahdi Sadeghi and Morteza Shahmoradi two professional engineers with an outstanding background in technologies and automation.

Team Member

Manager and Director

Contact US

Montréal, QC H4C 1L8

Involta © 2023 All Rights Reserved – Designed by TiSite